Sustainable aviation fuel (SAF) produced through HEFA (hydroprocessed esters and fatty acids) technology using Camelina oil (Camelina sativa) as feedstock is effective at reducing greenhouse gas (GHG) emissions along its supply chain compared to fossil jet fuel. The supply chain of Camelina-based SAF can achieve and exceed the 60% GHG emission reduction minimum requirement for biofuels set by REDII.

A report published in late 2020 by the BIO4A consortium carries out and environmental impact assessment of the supply chain of SAF in the form of a Life Cycle Analysis (LCA) to quantify the GHG emission (savings) for the production process of the biofuel the project aims to produce.

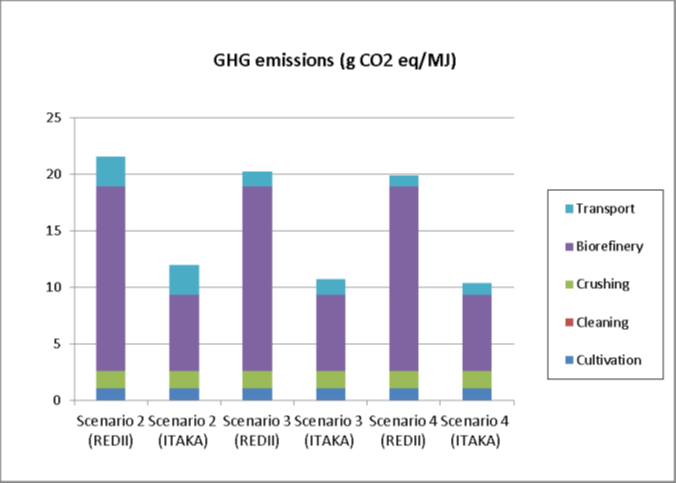

The scope of the LCA includes the cultivation (soil emission, fertilizer use etc.) of the feedstock (Camelina sativa), the processing (cleaning, crushing, oil extraction), the refinement technology used (HEFA), the combustion in jet engines and the transportation of the products between each of these steps. The functional unit of the analysis is grams of CO2 equivalent per mega joules (gCO2eq/MJ) of fuel produced and combusted. The base scenario studied in the report assumes that the feedstock is cultivated on degraded land and crushed to extract its oil in Spain, then shipped to France to be converted into jet biofuel, and finally used at Marseille’s Airport. Since the feedstock is assumed to be grown on degraded land, the SAF has a bonus GHG emission reduction of 29 gCO2eq/MJ due to incentives included in the EU’s REDII. Two other scenarios have been contemplated with different (European) locations for the different components of the supply chain. For each scenario, two different GHG emission values have been used for the refinement step (one, higher, provided by REDII, and the other, lower, by the ITAKA project, BIO4A’s predecessor), yielding two different overall GHG emission saving performances for each scenario.

The LCA shows that the GHG emissions of the supply chain studied range between 10.7 and 21.8 gCO2eq/MJ depending on the scenario considered; this amounts to a GHG emission savings rate between 73-87% compared to the fossil fuel baseline of 94 gCO2eq/MJ defined by REDII. The most GHG emission intensive component of the supply chain is the refinement stage, followed by transportation; these two are the components accounting for the great variability of the results of the LCA. Using the GHG emissions values for the refinement of feedstock provided by ITAKA drastically improves the overall performance of the production process, and so does (to a lesser degree) assuming that all the steps of the supply chain are carried out in the same country (e.g., France in Scenario 3). Even assuming that the feedstock is not cultivated on degraded land, if the ITAKA values are used, the supply chain would save 64% of GHG emissions, exceeding the minimum GHG emission reduction requirement of 60% set by REDII.

In conclusion, Camelina could be an effective feedstock to produce SAF, achieving substantial GHG emission mitigation especially if cultivated on previously degraded land.

Results for steps of the scenarios studied